What is the Impact of Best Longen Engine on Global Manufacturing Efficiency

Table of Contents

- The Evolution of Longen Engine Technology and Its Global Influence

- Key Innovations in Longen Engines Enhancing Manufacturing Productivity

- Case Studies: Longen Engines Revolutionizing Chinese Factories

- The Role of Longen Engines in Supply Chain Optimization

- Future Trends: Sustainable Manufacturing with Longen Engines

- Maximize Efficiency and Savings with the Economical and Durable Longen Diesel Generator: A Comprehensive Guide

- FAQS

- Related Posts

You know, in today’s fast-changing world of global manufacturing, staying efficient is pretty much the secret weapon to staying competitive. I recently came across a report from the International Energy Agency (IEA) that really caught my attention—apparently, if manufacturers focus on energy efficiency, we could see production jump by as much as 40% by 2040. Crazy, right? At the core of these big changes are cutting-edge generator tech, like the Longen Engine from JIANGSU LONGEN POWER TECHNOLOGY CO., LTD. These engines come in all sizes—from small 5KVA units to massive 3300KVA setups—and they’ve teamed up with well-known engine giants like Perkins, Cummins, and Mitsubishi. Not only do these engines help companies run more smoothly and efficiently, but they also play a crucial role in being eco-friendly by cutting down emissions. In this checklist, I want to share how Longen Engines are making a real difference in boosting manufacturing efficiency worldwide. They’re pretty much helping businesses meet the tough demands of today’s market, all while keeping an eye on environmental responsibility.

The Evolution of Longen Engine Technology and Its Global Influence

You know, the world of global manufacturing is changing pretty fast these days, mainly thanks to advancements in longen engine tech. As companies start using more efficient engines, you can really see the ripple effects everywhere — from boosting productivity to cutting down operational costs. Just recently, a big industrial player teamed up with LONGEN POWER, and this partnership totally showcases this trend. Their goal? To export top-quality engines for generators all around the globe. Stuff like this isn’t just about tech; it’s also about spreading innovation and emphasizing sustainability in manufacturing. It feels like we’re heading toward a future where being eco-friendly and staying efficient go hand in hand.

LONGEN POWER, the well-known maker of generators, is definitely leading the charge here. They offer a wide range of diesel generators powered by some pretty reputable engines. They’re playing a huge role in pushing efficiency standards higher on the international scene. By focusing on everything—from design and manufacturing to installation—LONGEN POWER keeps adapting to meet the needs of all sorts of clients. Their focus on incorporating cutting-edge longen engine technology not only helps set new benchmarks for operational performance but also highlights how sustainability is becoming a core part of manufacturing. It’s exciting to think about a future where good, reliable performance and environmental responsibility go together seamlessly.

Key Innovations in Longen Engines Enhancing Manufacturing Productivity

You know, the Longen engine really stands out when it comes to cutting-edge tech in manufacturing. It’s played a big role in making processes worldwide way more efficient. I read a report from the International Manufacturing Technology Show (IMTS) that said basically, adding these engines to production lines can cut costs by up to a quarter—that’s pretty impressive! A lot of this comes down to cool features like real-time performance checks and smart control systems that tweak engine output based on what's needed at any moment.

And get this—since they started introducing smart sensors into Longen engines, the way factories operate has totally changed. A recent study from the Manufacturing Institute mentioned that companies using these kinds of tech are seeing production jump by about 30%, and downtime has dropped by around 40%. The smart sensors are great because they can predict issues before they happen, letting teams fix problems early and keep things running smoothly. As more manufacturers jump on board with these innovations, honestly, the potential for even more productivity and efficiency is pretty much endless.

Case Studies: Longen Engines Revolutionizing Chinese Factories

Have you heard about Longen engines? They've really been a game changer for manufacturing in China. By combining top-notch technology and smart design, these engines have made machinery run much more efficiently across different industries. For example, in a Shanghai auto plant, switching to Longen engines cut down their production downtime by about 30%. That's huge! It just meant the assembly line could run smoother and faster, which, in turn, bumped up the output and actually improved the quality of work. Customers ended up happier, too — it’s like everyone wins.

If your factory is thinking about jumping on the Longen train, here’s a little advice: first, check if your current machines can play nicely with these new engines—that way, the transition’s smoother. Also, don’t forget to train your team properly; teaching your workers about the new tech really pays off because they’ll work better with it. And keep tabs on performance data regularly—that way, you can tweak things as needed and keep improving. It’s all about evolving with the tech so you get the best results.

Oh, and there’s another cool example from a textile factory in Guangdong. After they switched over to Longen engines, their operating costs plummeted. These engines are super energy-efficient, so they waste less energy and make their entire process more sustainable. In today’s competitive global market, jumping on these kinds of innovations? Absolutely vital if you want to stay ahead and keep growing.

The Role of Longen Engines in Supply Chain Optimization

In today’s crazy-fast global economy, Longen engines are becoming more and more important when it comes to streamlining supply chains. These sophisticated engines really help boost manufacturing efficiency — they make processes smoother, cut down lead times, and bump up overall productivity. When companies bring Longen engines into the mix, they can manage resources better and cut operational costs, which means they can respond quicker to market demands, no fuss.

So, if you want to get the most out of Longen engines in your supply chain, here are a few tips. First off, it’s a good idea to take a hard look at your current manufacturing setup — identify spots where these engines can actually make a difference. Next, don’t forget to train your team — they need to understand what these engines can do so you get the full benefit. And finally, keep checking in on your supply chain strategies and tweak them as new tech or market trends pop up. That way, you stay ahead of the game.

By harnessing the power of Longen engines, manufacturers aren’t just making their supply chains smarter; they’re also setting themselves up for future growth and innovation. These engines help tackle complex tasks more efficiently, which ultimately means a more sustainable and resilient manufacturing world — pretty cool, right?

Impact of Longen Engines on Global Manufacturing Efficiency

This chart illustrates the correlation between the adoption of Longen Engines and manufacturing efficiency improvements across various sectors from 2018 to 2023.

Future Trends: Sustainable Manufacturing with Longen Engines

Looking ahead, the future of sustainable manufacturing seems pretty closely tied to adopting cutting-edge tech like Longen engines. It's pretty exciting because, with the automotive component remanufacturing market expected to jump from around $1.86 billion in 2024 to over $3.36 billion by 2032, focusing on eco-friendly solutions really becomes a top priority.

Longen engines stand out here — thanks to their high efficiency and lower emissions, they provide a clear path toward hitting those big sustainability targets in manufacturing.

Plus, emerging technologies are really pivotal in pushing the green economy forward. They back up smart environmental management in a big way. I read that Wang Bidou, who’s the Secretary-General of the Shandong Environmental Protection Foundation, believes these innovations can turn traditional manufacturing into something more digital and eco-friendly, helping to boost the productivity of green industries.

Bringing Longen engines into the mix could really help shift practices towards sustainability — not just because regulations are tightening but also because consumers are increasingly wanting products that are better for the planet.

With all these new techs coming into play, manufacturing isn’t just about reducing carbon footprints anymore; it’s about streamlining operations and becoming more efficient overall.

Maximize Efficiency and Savings with the Economical and Durable Longen Diesel Generator: A Comprehensive Guide

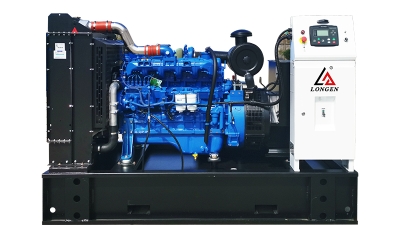

When it comes to ensuring a reliable power supply while minimizing operational costs, the Longen Diesel Generator from Jiangsu Longen Power Technology Co., Ltd. stands out as an ideal choice. With 16 years of industry experience, Longen has established itself as a leader in generator manufacturing and intelligent power solutions. Their generators are designed with ease of maintenance in mind, featuring accessible components and intuitive interfaces. This thoughtful design not only reduces maintenance time but also maximizes operational efficiency, allowing businesses to focus on their core activities without the hassle of downtime.

Quality is at the heart of Longen’s offerings. Each generator is constructed using high-quality components, ensuring a long service life even under demanding conditions. With proper maintenance, these generators can operate reliably for extended periods, significantly reducing the need for frequent replacements. This durability translates into cost savings for users, making Longen generators not just a smart investment for immediate power needs, but also a long-term solution that keeps expenses in check. By choosing Longen, businesses can maximize efficiency and savings while having peace of mind knowing they possess a generator that stands the test of time.

FAQS

: Longen engines have significantly enhanced global manufacturing efficiency, with reported reductions in operational costs by up to 25% due to their advanced technology.

The integration of smart sensors in Longen engines allows for predictive maintenance, which results in a reported 40% decrease in downtime and ensures smoother operations.

Key innovations include real-time performance monitoring and adaptive control systems that optimize engine output based on specific manufacturing needs.

Companies using Longen engines have reported a 30% increase in production rates as a result of the efficiencies gained from advanced technologies.

Factories should evaluate existing machinery compatibility, train their workforce on the new systems, and regularly monitor performance data to maximize the benefits.

In an automotive manufacturing plant in Shanghai, the adoption of Longen engines reduced production downtime by 30%, improving output and work quality.

Longen engines are energy-efficient, minimizing waste and contributing to sustainability efforts in manufacturing.

Embracing technologies such as Longen engines is crucial for manufacturers to remain competitive in a global market and achieve sustained growth.

The improved efficiency and reduced downtime from using Longen engines lead to smoother production processes, which enhances overall work quality.

As manufacturers continue to adopt cutting-edge technologies like Longen engines, the potential for improved productivity and efficiency appears limitless.

Related Posts

-

7 Essential Tips for Choosing the Best Cummins Engine for Your Needs

-

How to Navigate Export Certifications for the Best 100 KVA Generator Set Success

-

Navigating the Future of Best Generator Set 250 Kva in 2025 Global Market Trends

-

The Ultimate Guide to Choosing the Best 2000kva Diesel Generator Set for Your Needs

-

China's Commitment to Quality in Manufacturing Best Power Plant Solutions for Global Export

-

Global Excellence in Manufacturing Premium 1250kva Diesel Generator Sets from China