The Ultimate Guide to Choosing the Right 300kw Generator for Your Industrial Needs

Table of Contents

- Understanding the Importance of Selecting the Right 300kw Generator for Industry

- Common Issues Faced with Improper Generator Type Selection

- Key Factors to Consider When Choosing a 300kw Generator for Your Operations

- How to Evaluate Different Generator Types for Industrial Applications

- Cost Implications of Using the Wrong Generator Type in Your Business

- FAQS

- Conclusion

- Related Posts

In today’s industrial world, reliable power is more important than ever, and picking the right generator can actually make or break your operations. If you're on the hunt for a 300kW generator, you’re in the right place — that’s a solid size for so many medium to large projects.

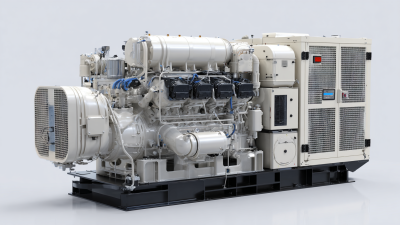

Now, let me tell you a bit about JIANGSU LONGEN POWER TECHNOLOGY CO., LTD. — they’re pretty much experts when it comes to making high-quality diesel generators. They offer a bunch of engine options like Perkins, Cummins, and Volvo, plus top-notch alternators such as Stamford and Leroy Somer.

Now, let me tell you a bit about JIANGSU LONGEN POWER TECHNOLOGY CO., LTD. — they’re pretty much experts when it comes to making high-quality diesel generators. They offer a bunch of engine options like Perkins, Cummins, and Volvo, plus top-notch alternators such as Stamford and Leroy Somer.

With their deep experience in design, manufacturing, sales, and support, they really know how to help you find the perfect 300kW generator for your specific needs. Whether you’re setting up a new facility or just upgrading your current power setup, understanding what to look for in a generator is key — trust me, it’s worth taking the time to get it right.

Understanding the Importance of Selecting the Right 300kw Generator for Industry

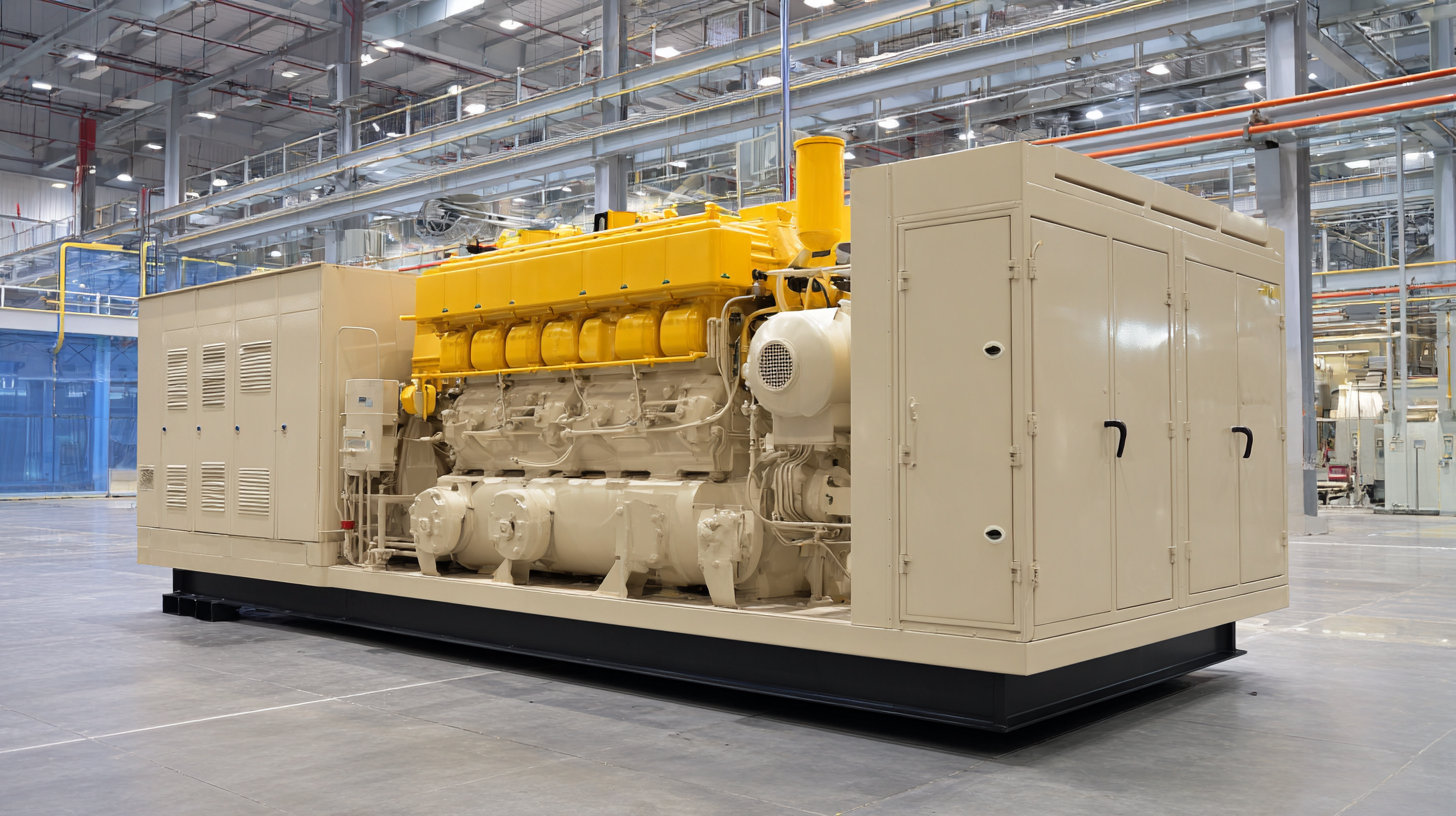

When you're looking to pick out a 300kW generator for industrial use, it’s really important to understand just how crucial it is to choose the right one. Not too long ago, China rolled out its very first hydrogen internal combustion engine generator — which is pretty exciting!

This breakthrough really shows how the energy landscape is shifting for industries. It’s a big step forward, especially as more folks are searching for options that not only boost efficiency but also align with sustainability goals.

Picking the right generator isn’t just about checking specs. You’ve gotta think about what’s actually needed for your specific operation. Things like what fuel it uses, how much maintenance it’ll need, and whether it plays nice with your existing setup all matter a lot.

And with innovations like this new hydrogen generator hitting the market, industries now have eco-friendlier choices that can cut emissions and save some cash on running costs.

At the end of the day, making an informed decision means considering not just your current needs but also what the future of energy looks like — it’s all about staying ahead of the game.

And with innovations like this new hydrogen generator hitting the market, industries now have eco-friendlier choices that can cut emissions and save some cash on running costs.

At the end of the day, making an informed decision means considering not just your current needs but also what the future of energy looks like — it’s all about staying ahead of the game.

Common Issues Faced with Improper Generator Type Selection

When you're out there trying to pick a 300kW generator for your industrial setup, not choosing the right type can cause some real headaches. It might lead to stuff like your operations getting pushed back or costs creeping up unexpectedly. The International Energy Agency even pointed out that if your generator’s capacity doesn’t quite match your actual needs, it can waste fuel pretty badly — we're talking over 30% higher operational costs. Plus, if your generator isn't the right size, it could be under a lot of strain, which means more frequent repairs and a higher chance of breakdowns. Not exactly ideal, right?

To avoid these kinds of issues, it’s super important to do a detailed load analysis beforehand. You want to figure out both your peak needs and the usual, steady requirements — so your generator can handle those surprise surges without breaking a sweat. Also, it’s worth thinking about fuel types and environmental impacts. Since regulations are tightening around emissions, industries are leaning more towards cleaner options like natural gas.

A few tips? Going for a generator with a better efficiency rating can really help you save on fuel. Don't forget to keep up with regular maintenance — catching small problems early can save you a ton in repair costs later. And, if you can, chat with industry experts or use an energy management system to keep an eye on your power needs all the time. Trust me, little tweaks like these can make a big difference!

The Ultimate Guide to Choosing the Right 300kw Generator for Your Industrial Needs - Common Issues Faced with Improper Generator Type Selection

| Criteria | Common Issues | Impact | Solution |

|---|---|---|---|

| Load Requirements | Under or Overloading | Reduced efficiency, potential damage | Accurate load calculation; choose the right capacity |

| Fuel Type | Incompatibility with system | Increased operational costs, downtime | Evaluate available fuel options and requirements |

| Generator Type | Choosing wrong type (diesel vs. gas) | Lower performance or compliance issues | Research benefits of each type for your needs |

| Maintenance | Neglecting regular servicing | Unexpected failures, costly repairs | Establish a routine maintenance schedule |

| Noise Level | Excessive operational noise | Regulatory fines, neighbor complaints | Choose a generator with noise reduction features |

| Location | Improper siting causing overheating | Reduced lifespan, operational issues | Ensure adequate ventilation and spacing for installation |

Key Factors to Consider When Choosing a 300kw Generator for Your Operations

When you're picking out a 300kW generator for your industrial setup, there are a few key things you really want to keep in mind to make sure everything runs smoothly and efficiently. First off, it's super important to get a clear picture of your power needs. I mean, did you know that, according to the U.S. Energy Information Administration, the commercial and industrial sectors make up over 40% of the country’s total energy use? That’s a huge chunk, so choosing a dependable power source is pretty much essential. Take a good look at your peak loads, any potential growth you’re planning down the line, and what exactly you’ll be using the generator for — that’ll help you figure out if a 300kW unit is the right fit.

Another thing to think about is the type of fuel. This really can change the game when it comes to operational costs and overall efficiency. A recent report from the International Energy Agency mentioned that diesel generators are still the most common—no big surprise there—but they’re gradually being edged out by options like natural gas and renewable energy sources. Each has its perks: diesel tends to be reliable and last a long time, but natural gas is cleaner and can be cheaper to run. Also, don’t forget to check out what kind of maintenance is involved and whether support is easily available for the generator you pick. These little things can add up and affect your ongoing costs and how long your setup stays up and running.

The Power Output Comparison of 300kW Generators

How to Evaluate Different Generator Types for Industrial Applications

When you're trying to decide between different types of generators for industrial use, it all starts with really thinking about your specific power needs. For instance, if you're looking at a 300kW generator, it’s not just about covering your current energy demands — you also want something that can handle possible growth down the line. It’s a good idea to look at your peak load requirements, making sure the generator can manage those sudden surges without any hiccups. Plus, don’t forget to check out how efficient different models are, because that will impact both your running costs and how eco-friendly your operation is.

Then, it’s worth considering the fuel options for each type. Diesel generators are often praised for their toughness and efficiency, so they’re a common pick for heavy-duty applications. On the other hand, natural gas generators might offer you lower emissions and save some money on fuel — which is a big deal if you're trying to be more sustainable. Don’t overlook the maintenance side of things either; figuring out how often each generator needs service and how easy it is to get support can really make a difference in the long run. Basically, picking the right generator is about balancing the costs and benefits — considering both the initial investment and what you’ll spend on maintenance over time — to make sure you’re making a smart, financially sound choice.

Cost Implications of Using the Wrong Generator Type in Your Business

When you're choosing a 300kW generator for your industrial setup, it’s pretty clear that picking the wrong type can have major cost implications — and honestly, that can’t be stressed enough. Every generator has its own quirks — some are more efficient, others might need more maintenance, and their operating costs can vary a lot. If you end up with a generator that doesn’t really fit your needs, you could be wasting energy like crazy, which means higher electricity bills and, in turn, eating into your profits. Not to mention, if the power supply isn’t stable enough, it can cause production delays, equipment breakdowns, and some serious financial headaches down the road.

On top of all that, the environmental impact of mismanaging generators is becoming a big deal these days. Think about how the surge in generative AI models raises eyebrows over increased electricity and water use — well, poorly chosen generators do the same thing. They end up draining resources more than necessary, putting a strain on local utilities and the environment.

So, it’s really important for businesses to take a close look at their power needs and pick a generator that balances both cost-effectiveness and environmental responsibility. That way, you’re not just saving money, but also making sure your operations stay sustainable in the long run.

FAQS

: When selecting a 300kw generator, key factors include fuel type, maintenance requirements, compatibility with existing systems, and the specific power demands of your operation.

Choosing the correct type of generator is crucial as improper selection can lead to inefficient fuel consumption, increased operational costs, frequent maintenance requirements, and a higher risk of breakdowns.

A load analysis helps ensure that the generator can handle both peak and continuous load requirements, preventing operational disruptions caused by unexpected demand surges.

Environmental considerations involve assessing the gas emissions associated with different fuel types, with a growing trend towards cleaner alternatives like natural gas and hydrogen generators to meet tightening regulations.

Higher efficiency generators maximize fuel usage, leading to lower operational costs, while inefficient generators can contribute to greater expenses due to increased fuel consumption.

Regular maintenance checks can prevent minor issues from developing into costly repairs, thus ensuring the generator operates reliably and efficiently over time.

It is important to analyze both upfront investment costs and ongoing operational expenses to ensure a sound financial decision that balances performance and budget considerations.

Diesel generators are known for their durability and efficiency, making them suitable for heavy industrial use, while natural gas generators typically offer lower emissions and reduced fuel costs, appealing to sustainability-focused companies.

The launch of hydrogen generators represents a significant evolution in the market, providing industries with cleaner energy options that align with sustainability goals while ensuring operational efficiency.

If energy demands change, it’s advisable to reassess the generator's capacity and performance, possibly conducting a new load analysis to evaluate whether the existing generator remains adequate or if an upgrade is necessary.

Conclusion

Picking the right 300kW generator for your industrial setup is super important if you want things to run smoothly and reliably. Honestly, understanding why choosing the right type really matters can save you from a ton of headaches—like unexpected downtime or those sneaky costs that pile up when you pick the wrong one. When you're shopping around, think about what your operations actually need in terms of power, what kind of load the generator’s gonna handle, and how efficient different models really are.

It’s also a good idea to check out different options, especially models from places like JIANGSU LONGEN POWER TECHNOLOGY CO., LTD. They’ve got a pretty wide range of diesel generator sets, all with solid engines and alternators. Picking the right 300kW unit isn’t just about what looks good on paper—it can seriously boost your business’s performance and save you money in the long run. Skimp on the research, though, and you could end up with some costly surprises, so it’s worth taking the time to do your homework before making a final decision.

Related Posts

-

Innovative Applications of Powered By Mtu in Diverse Industries

-

Embracing the Future: How the 2025 Technology Trends are Shaping the Best 11kva Generator Market

-

Solutions for Powering Up Your Business with 70 Kva Generator Insights and Benefits

-

Exploring Alternative Power Solutions: Beyond Diesel Generators for Sustainable Energy

-

2025 Market Trends & How the Best 1.5MW Generator Set Powered By MTU Can Lead Your Business

-

What is the Impact of Best Longen Engine on Global Manufacturing Efficiency

Blog Tags: