Understanding Controller in Control System for 2025 Top Applications and Trends

Table of Contents

- Definition and Role of Controllers in Control Systems

- Key Components of Control Systems: Understanding Controllers

- Types of Controllers: PID, Fuzzy Logic, and More

- Trends in Control System Applications for 2025

- Challenges in Designing Effective Control Systems

- Future Technologies Influencing Controller Development

- Case Studies: Successful Implementations of Controllers in 2025

- Harnessing Clean Power: A Comprehensive Guide to NEW ENERGY BATTERY ENERGY STORAGE SYSTEM (BESS) Integration and Benefits

- FAQS

- Conclusion

- Related Posts

In the fast-changing world of automation and tech, the role of the 'Controller In Control System' has become more important than ever. I was reading a report by MarketsandMarkets, and it blows my mind—it's estimated that the global market for industrial automation will hit around $295 billion by 2025. That just goes to show how much companies are really craving those advanced control systems across all sorts of industries. As leaders try to boost efficiency and get more precise results, the need for reliable controllers to handle complex processes is pretty obvious.

Dr. Emily Johnson, a real expert in control systems, puts it simply: 'A well-designed controller is basically the backbone of any successful control system. It helps everything run smoothly and makes real-time decisions possible.' I think that really hits home. It just highlights why we’ve got to keep pushing innovation in controller tech—especially now, with industry challenges coming from all directions, from manufacturing to smart energy grids.

Looking ahead to 2025 and beyond, it’s clear that these advancements in 'Controller In Control System' tech are going to shake up how things are done in a big way. The integration of AI, machine learning, and the Internet of Things with control systems is set to change the game entirely. Looks like the future will be all about smarter, more efficient control strategies that can seriously boost productivity and help companies operate at their best.

Definition and Role of Controllers in Control Systems

Controllers play a pivotal role in control systems, serving as the brains behind the processes they manage. At their core, controllers are designed to apply algorithms and rules that ensure systems operate within defined parameters. They continuously monitor system outputs, compare them with desired setpoints, and make necessary adjustments to minimize the error. This feedback loop—often referred to as closed-loop control—enables stability and precision in various applications ranging from manufacturing to robotics and automated systems.

In addition to their fundamental function, modern controllers are evolving to meet the demands of emerging technologies. The integration of machine learning and artificial intelligence is transforming how controllers operate, allowing for predictive capabilities and adaptive responses. This advancement not only enhances efficiency but also enables systems to learn from past performance, optimizing operations over time.

As industries prepare for increased automation and smart technologies in 2025 and beyond, the role of controllers will become increasingly sophisticated, focusing on real-time data processing and decision-making to address complex challenges in dynamic environments.

Key Components of Control Systems: Understanding Controllers

In 2025, the role of controllers in control systems is expected to evolve significantly, owing to advancements in technology and the increasing complexity of applications across various industries. Controllers are essential components that facilitate the regulation of processes by managing the output based on the desired input—a function critical for ensuring system stability and performance. According to a report by MarketsandMarkets, the global control system market is projected to reach $26.7 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.7% from 2021 to 2026. This growth is largely driven by the integration of advanced automation technologies and the increasing demand for efficiency in manufacturing and production processes.

One of the key trends shaping the future of controllers is the rise of intelligent control systems, incorporating artificial intelligence and machine learning algorithms. These technologies enable controllers to learn from historical data, improve decision-making processes, and optimize real-time operations. A study from Frost & Sullivan indicates that AI in control systems could improve operational efficiency by up to 30%, drastically reducing downtime and enhancing productivity. Additionally, the adoption of cloud-based solutions for control systems is gaining momentum, allowing for remote monitoring and management, further empowering organizations to streamline their operations and respond more swiftly to market changes. These advancements underscore the vital role of controllers in not just maintaining but enhancing the performance of control systems in diverse sectors, from manufacturing to renewable energy.

Understanding Controller in Control System for 2025 Top Applications and Trends - Key Components of Control Systems: Understanding Controllers

| Application Area | Controller Type | Key Functionality | Emerging Trends | Challenges |

|---|---|---|---|---|

| Industrial Automation | PID Controller | Maintains process control by adjusting output based on error | Increased integration with IoT | Complex systems require more tuning |

| Smart Buildings | Fuzzy Logic Controller | Handles imprecision in control decisions | Increased focus on energy efficiency | Adapting to user preferences |

| Robotics | Model Predictive Controller | Predicts future behavior to optimize control | Integration of AI for better decision making | High computational cost |

| Aerospace | Adaptive Controller | Adjusts control strategies based on changing conditions | Development of autonomous systems | Safety and reliability concerns |

| Transportation | Linear Quadratic Regulator | Optimizes control actions to minimize cost | Smart traffic management systems | Infrastructure limitations |

Types of Controllers: PID, Fuzzy Logic, and More

Controllers play a crucial role in modern control systems, shaping how processes are managed in various applications. Among the most widely used types of controllers are Proportional-Integral-Derivative (PID) controllers and fuzzy logic controllers. PID controllers are renowned for their simplicity and effectiveness, allowing for precise control by continuously calculating an error value and applying corrective actions based on proportional, integral, and derivative terms. This makes them suitable for a wide range of industries, from manufacturing to aerospace, where maintaining optimal performance is essential.

On the other hand, fuzzy logic controllers offer a more adaptable approach to managing systems that are too complex or uncertain for traditional methods. By simulating human reasoning, fuzzy logic can handle imprecise inputs and provide robust control in situations where system dynamics are not easily quantifiable. This characteristic makes fuzzy logic increasingly popular in applications such as environmental control and robotics, where conventional strategies might fall short. As 2025 approaches, the integration of these controller types will likely expand, embracing advancements in technology and addressing the challenges of evolving industrial landscapes.

Trends in Control System Applications for 2025

As we look toward 2025, the landscape of control system applications is evolving rapidly, driven by advancements in technology and increasing demand for automation and efficiency across various industries. One of the most significant trends is the integration of artificial intelligence and machine learning into control systems. These technologies enable systems to learn from data, making real-time adjustments that enhance performance and reliability. Industries such as manufacturing, where precision and efficiency are critical, are beginning to adopt these smart control systems, resulting in improved production processes and reduced downtime.

Another notable trend is the proliferation of IoT-connected devices, which are transforming traditional control systems into interconnected networks. This shift allows for better monitoring and control of processes, enabling predictive maintenance and optimizing resource usage. In sectors like energy management and smart cities, these developments are fostering a more sustainable approach to operations. By leveraging data from various sources, control systems can optimize performance and lead to more informed decision-making, ultimately paving the way for smarter, more responsive environments in the years to come.

Challenges in Designing Effective Control Systems

In the pursuit of advancing control systems, the challenges in designing effective controllers have become increasingly complex. According to recent reports by the International Society for Automation, around 55% of control system failures can be attributed to inadequate design and implementation practices. This highlights the critical need for engineers to innovate on existing methodologies to mitigate risks and enhance reliability in control systems. As automation and IoT applications grow, the requirement for robust controllers that can withstand dynamic changes becomes imperative, necessitating a reevaluation of design frameworks and criteria.

One of the primary challenges is the integration of machine learning algorithms into control systems. A study by McKinsey projects that by 2025, over 70% of control systems will leverage AI-driven strategies to adapt in real-time to changing environments. However, achieving this integration isn’t straightforward; it requires a deep understanding of both system dynamics and advanced computational techniques. Additionally, designers must navigate complexities associated with data management and latency issues. The push for Industry 4.0 trends demands that control systems not only function autonomously but also communicate effectively across platforms, complicating the overall design process further. As such, innovative approaches are essential to streamline control systems to meet these burgeoning expectations while maintaining high performance and reliability.

Future Technologies Influencing Controller Development

The evolution of controller technologies is significantly influenced by various future trends and innovations across multiple sectors. Emerging technologies such as artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT) are transforming control system frameworks, enabling smarter, more efficient, and adaptive solutions. According to a recent report by MarketsandMarkets, the global IoT in industrial applications is projected to grow from $157 billion in 2020 to over $500 billion by 2025. This exponential growth underscores the increasing reliance on advanced controllers that can seamlessly integrate with IoT devices to enhance operational efficiency and data analytics capabilities.

Moreover, the advent of edge computing is reshaping how data is processed in real-time, allowing controllers to make decisions closer to the source of data collection. This not only reduces latency but also enhances the system's responsiveness to changing conditions. Research shows that edge computing can reduce communication bandwidth by up to 80%, making it a vital component in developing next-generation controllers.

Tips: When designing controllers for future applications, prioritize modular architectures that allow for easy upgrades and integration of new technologies. Keeping scalability in mind can greatly enhance the longevity and adaptability of your control systems. Additionally, investing in cybersecurity measures is crucial, as the rise of connected devices also increases vulnerability to cyber threats.

Case Studies: Successful Implementations of Controllers in 2025

In recent years, controller technologies have seen significant advancements, particularly in the context of automation and process control. Case studies from 2025 highlight the successful implementation of sophisticated controllers in various industries, demonstrating their transformative impact. For instance, a comprehensive report by the Control Systems Society indicates that organizations adopting advanced adaptive controllers have achieved efficiency improvements of up to 35% in manufacturing processes. This shift is fueled by the integration of machine learning algorithms, which enable controllers to optimize operations in real time, ultimately leading to reduced waste and enhanced productivity.

Another notable case involves the application of distributed control systems (DCS) in the energy sector. According to a 2025 industry analysis, companies implementing DCS noted a 30% reduction in downtime. This reliability is critical as energy demands continue to escalate, and maintaining operational efficiency becomes paramount for sustaining output levels. Furthermore, the flexibility of modern controllers allows for seamless upgrades and integration with IoT devices, paving the way for smarter energy grids. Organizations that embrace these technologies are not only improving their operational capabilities but also supporting sustainability goals through more efficient resource management.

Harnessing Clean Power: A Comprehensive Guide to NEW ENERGY BATTERY ENERGY STORAGE SYSTEM (BESS) Integration and Benefits

The modern energy landscape is rapidly evolving, emphasizing the need for sustainable and efficient energy solutions. Battery Energy Storage Systems (BESS) are at the forefront of this transition, providing significant advantages in energy management and optimization. By integrating renewable energy sources, such as solar and wind, with advanced battery technology, industries can effectively balance supply and demand while enhancing grid stability. According to a report by the International Energy Agency, the global energy storage market is projected to reach 1,095 GWh by 2040, signifying the critical role BESS will play in the future of energy infrastructure.

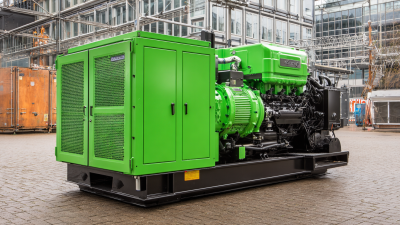

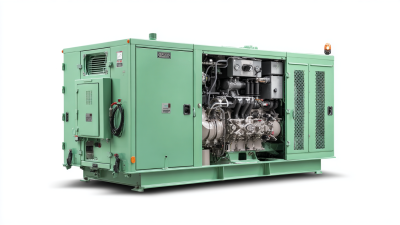

A noteworthy development in this field is the introduction of advanced energy storage systems designed for various applications. Contemporary BESS technologies accommodate diverse environments, such as industrial and commercial settings, as well as residential use. These systems are engineered to meet high load requirements, making them suitable for temporary electricity use or as backup power solutions. Moreover, findings from the U.S. Department of Energy indicate that integrating energy storage can reduce electricity costs by up to 30%, showcasing the economic benefits alongside sustainability.

The versatility of modern BESS allows for seamless compatibility with electric grids, photovoltaic equipment, and even diesel generators. This adaptability not only highlights the importance of flexible energy solutions but also encourages the widespread adoption of clean power technologies across different sectors. As battery solutions continue to advance, they will undoubtedly play a pivotal role in achieving energy independence and combating climate change, driving the transition to a greener economy.

FAQS

: The global control system market is projected to reach $26.7 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.7% from 2021 to 2026.

Intelligent control systems, which incorporate artificial intelligence and machine learning algorithms, enable controllers to learn from historical data and optimize real-time operations, significantly enhancing decision-making and operational efficiency.

Organizations using advanced adaptive controllers have reported efficiency improvements of up to 35% in manufacturing processes.

Companies implementing distributed control systems have experienced a 30% reduction in downtime, which is crucial for meeting increasing energy demands and maintaining operational efficiency.

The adoption of cloud-based solutions for control systems allows for remote monitoring and management, which can help organizations streamline operations and respond more quickly to market changes.

Controllers are essential for regulating processes by managing outputs based on desired inputs, which is critical for ensuring system stability and performance across various industries.

The integration of AI in control systems can improve operational efficiency by up to 30%, leading to reduced downtime and enhanced productivity.

The flexibility of modern controllers allows for seamless upgrades and integration with IoT devices, facilitating the development of smarter energy grids.

Various industries including manufacturing and renewable energy are benefiting from advancements in controller technologies that optimize processes and support sustainability goals.

The reliability of controllers is crucial in the energy sector to maintain operational efficiency and support the escalating energy demands.

Conclusion

The article "Understanding Controller in Control System for 2025 Top Applications and Trends" explores the integral role of controllers in control systems and their pivotal function across various applications. It starts with a clear definition of controllers and their significance in maintaining system stability and performance. The discussion includes key components of control systems, particularly focusing on the different types of controllers such as PID and fuzzy logic, which are essential for improving operational efficiency.

As we look towards 2025, the article highlights emerging trends in control system applications, emphasizing the potential challenges designers face in creating effective solutions. Innovations in technology are set to influence the development of controllers, leading to more sophisticated and adaptable systems. Additionally, the article presents case studies that showcase successful implementations of controllers in various sectors, demonstrating their vital contribution to modern engineering practices. Through this comprehensive overview, it becomes evident that the "Controller in Control System" remains a cornerstone for advancements in automation and industrial processes.

Related Posts

-

Exploring the Future of Diesel Power Stations at 2025 China Import and Export Fair: Industry Insights and Data

-

How to Choose the Right 20kw Diesel Generator for Your Business Needs

-

The Ultimate Guide to Choosing the Best Silent Diesel Generator for Your Business Needs

-

Ultimate Guide to Choosing the Right Doosan Container Generator for Your Needs

-

Unleash Adventure: Top 5 Good Portable Power Stations for Outdoor Enthusiasts

-

Understanding Tower Obstruction Lighting: Essential Safety Measures for Aviation and Navigation

Blog Tags: